The history of the "Ostrowiec Foundry" dates back to the early 19th century.

In the inter-war period, the Foundry was part of "Zakłady Ostrowieckie", after 1945 it was incorporated into Huta Marcelego Nowotki and then Huta Ostrowiec.

Since 1995 the foundry belonged to Ostrowiec Works, which was separated from Huta Ostrowiec. On 1st of July 1997 Zakłady Ostrowieckie spun off "Odlewnie Ostrowieckie" as an independent enterprise - a limited liability company.

From 2003 to 2004, Odlewnia functioned together with Ciepłownia as Energetyka Cieplna and Odlewnie Ostrowieckie spółka z o.o.

In 2005, due to the discontinuation of heat production, the company's name was changed to "Odlewnia Ostrowiec" spółka z o.o.

Odlewnia Ostrowiec produces single units, small batch and medium batch castings made of steel.

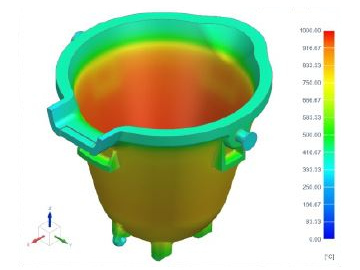

The foundry specialises in the production of ladles for the steel, copper, tin and lead industries. In addition, it produces other castings up to 30 tonnes for the metallurgical, cement, energy, mining, engineering, shipbuilding and construction industries.

In addition to domestic customers, the main customers for castings are from Europe and the USA.